In the fast-paced world of equipment repair, your parts inventory isn't just a storage room—it's the lifeline of your business. Yet many repair shops are hemorrhaging money through their inventory management without even realising it. After two decades of working with repair businesses, I've witnessed the devastating impact of poor inventory practices on otherwise profitable operations.

Picture walking into a typical repair shop plagued by inventory problems. Technicians frantically search through overflowing shelves for a critical part, while boxes of rarely-used components gather dust in the corner. The owner, struggling with cash flow, can't understand why there's simultaneously too much inventory and never enough of the right parts. This scenario plays out daily across thousands of repair businesses, each one bleeding money through invisible wounds in their inventory system.

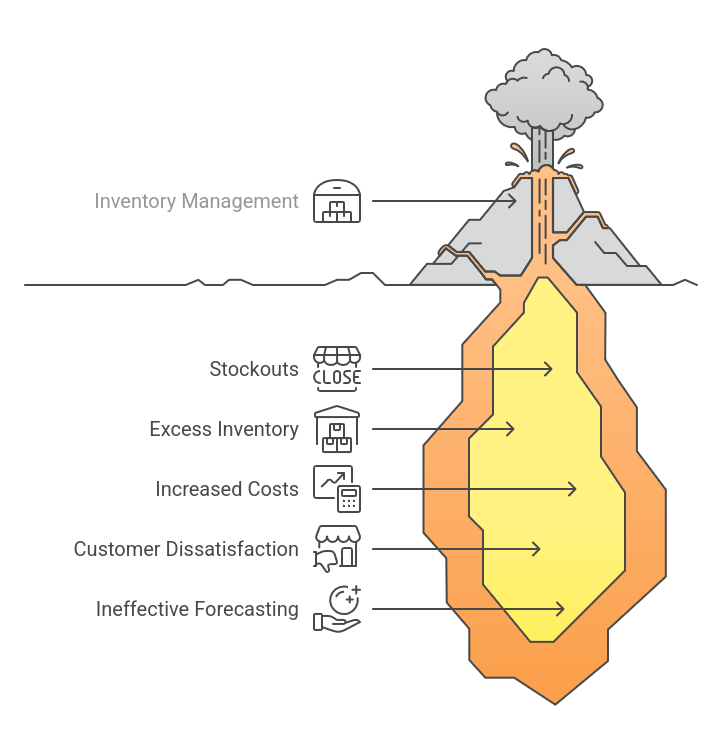

The heart of the problem lies in how repair shops historically manage their parts inventory. When a technician encounters a stockout during a critical repair, leading to a delayed job and an unhappy customer, the natural reaction is to overcompensate. Management orders extra parts "just in case," creating a vicious cycle that spirals out of control. Overstocking consumes valuable warehouse space and ties up working capital in slow-moving parts, while stockouts continue to occur because the budget is locked up in excess inventory.

Here's what makes inventory carrying costs so insidious: they typically represent between 20% and 30% of your inventory value annually, encompassing storage space, insurance, depreciation, and the opportunity cost of tied-up capital. When inventory management goes wrong, these costs compound exponentially, as shown in our analysis:

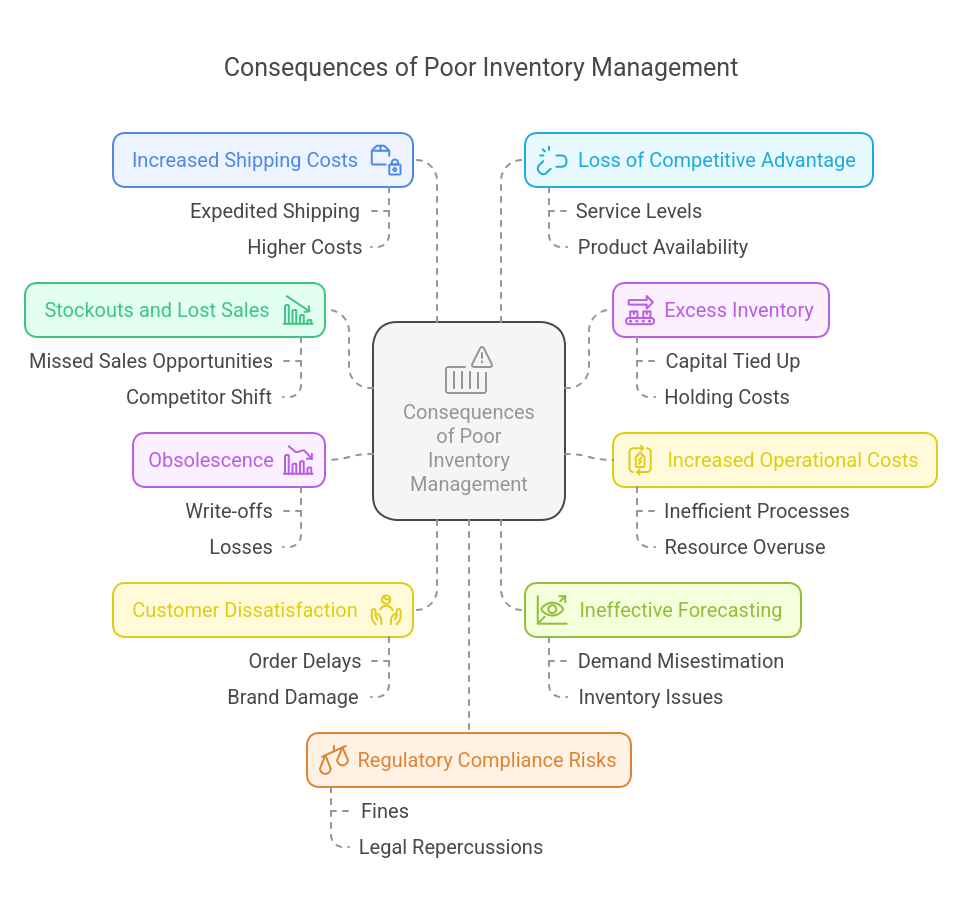

Hidden Costs of Poor Inventory Management

- Stockouts and Lost Sales

- When inventory levels are not properly managed, businesses may experience stockouts, leading to lost sales opportunities. Customers may turn to competitors if their desired products are unavailable.

- Excess Inventory

- Over-ordering can result in excess inventory, which ties up capital and incurs additional holding costs such as storage, insurance, and spoilage.

- Increased Operational Costs

- Poor inventory management can lead to inefficient processes, requiring more labour and resources to track and manage inventory, ultimately increasing operational costs.

- Obsolescence

- Products that remain unsold for extended periods may become obsolete, leading to write-offs and losses. This is particularly relevant in industries with rapidly changing trends.

- Customer Dissatisfaction

- Inconsistent inventory levels can lead to delays in order fulfilment, negatively impacting customer satisfaction and loyalty. This can result in long-term damage to a brand's reputation.

- Ineffective Forecasting

- Poor inventory management often stems from ineffective forecasting methods, leading to inaccurate demand predictions and further exacerbating inventory issues.

- Increased Shipping Costs

- Last-minute orders to replenish stock can incur higher shipping costs, especially if expedited shipping is required to meet customer demand.

- Loss of Competitive Advantage

- Companies that fail to manage their inventory effectively may struggle to compete with rivals who can offer better service levels and product availability.

- Regulatory Compliance Risks

- In some industries, poor inventory management can lead to compliance issues, resulting in fines or legal repercussions.

- Impact on Cash Flow

- Poor inventory practices can significantly affect cash flow, as funds are tied up in unsold stock rather than being available for other business operations.

The real killer lurking behind these issues is the integration gap. Most repair shops operate with disconnected systems for work orders, purchasing, and inventory management. Consider how this plays out in daily operations: a technician uses a part and records it in the work order system, but this information doesn't automatically update the inventory system or trigger a reorder when needed. This disconnect creates a perfect storm of manual processes, data entry errors, and delayed reactions to changing demand patterns.

These inventory management failures ripple throughout the entire business ecosystem. Technicians waste precious billable hours hunting for parts or waiting for deliveries. Customer satisfaction plummets as repair times stretch longer. Cash flow tightens while money sits idle on shelves in the form of excess inventory. Perhaps most frustratingly, shops often find themselves rushing to place emergency orders at premium prices for parts they actually need, while simultaneously sitting on thousands of dollars worth of slow-moving stock.

The five fundamental elements needed for effective inventory management form the cornerstone of any solution: integrated software connecting all business operations, automated reordering driven by usage patterns, strategic supplier relationships, systematic tracking processes, and regular performance analysis.

Breaking free from this cycle requires understanding that effective inventory management is a holistic system, not a series of independent decisions. Modern inventory management must integrate seamlessly with business operations, using real-time data to inform stocking decisions. Success demands more than just implementing new technology—it requires a fundamental shift in how repair shops approach their entire parts management strategy.

The transformation begins with a thorough assessment of current inventory metrics. Understanding your true carrying costs, turnover rates, and stockout frequencies establishes a baseline for improvement. While modern inventory management solutions can revolutionise operations, technology alone isn't the answer. Real success comes from combining smart systems with process improvement and data-driven decision-making.

Your parts inventory should be a strategic asset that supports business growth, not a money pit that drains resources. By addressing these hidden costs and implementing integrated solutions, repair shops can transform their inventory management from a source of constant frustration into a competitive advantage. The return on investment typically becomes apparent within months, as carrying costs decrease and technician efficiency improves. The key lies in taking that first step toward change, recognising that every day of delay is another day of preventable losses.